When discussing the Factory of the Future, the focus is often on vertical integration within the factory. But horizontal upstream and downstream integration throughout the supply chain is equally important.

For many pharma companies seeking to optimize and digitize their production, a top priority is often to ensure vertical integration between critical systems within the production site.

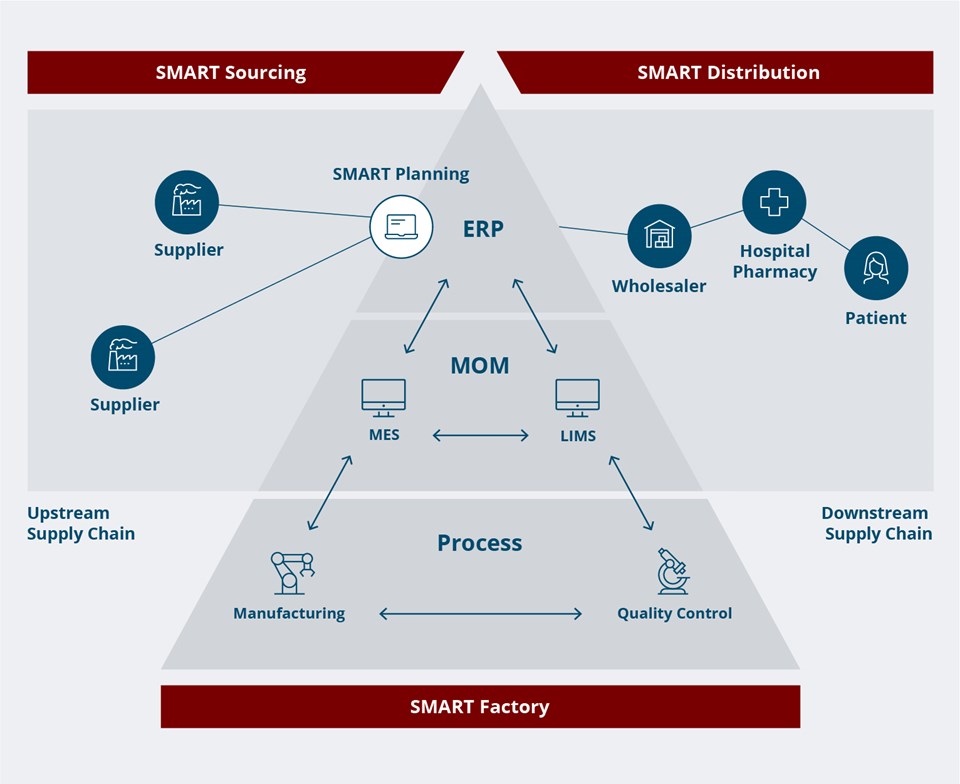

Typically, companies focus on implementing and connecting systems such as the Manufacturing Execution System (MES), Laboratory Information Management System (LIMS) and the production floor equipment. However, a full horizontal integration of the upstream and downstream supply chain also plays a vital role in the Factory of the Future.

An integrated upstream and downstream supply chain can greatly benefit both pharma companies and patients by providing a more efficient and effective distribution of medications, improving treatment and ensuring reliable tracking from active ingredients to consumed product.

Improve the flow of information

In traditional Pharma upstream activities in the pharma supply chain refer to the production and sourcing of raw materials, while downstream activities focus on the distribution and dispensing of medications to patients. By integrating these two aspects of the supply chain tightly with manufacturing, pharma companies can improve the overall flow of materials and information, leading to better coordination and collaboration between different stakeholders.

For novel therapies such as cell & gene therapies, a fully integrated and robust supply chain is absolute vital. It starts from the scheduled collection of patient samples, managing the transportation and logistics from the hospital to the manufacturing facility, tracking the patient samples throughout the manufacturing process, and finally delivering the therapeutic treatment back to that same patient. This patient-to-patient, also referred as needle-to-needle, supply chain process is becoming increasingly complex and critical with increasing numbers of patients. Crucial information like Chain of Identity, Chain of Custody, or cold chain information must be managed throughout the entire supply chain process: upstream from the patient to the manufacturing facility, within manufacturing and downstream to the patient.

Says Greg Cathcart, CEO at Excellis Health Solutions, LLC, an NNIT Group company:

The Factory of the Future should be regarded as a node in the supply chain of the future. Just as improved vertical integration and connectivity adds value within a production site, horizontal integration can also provide numerous benefits when applied to the upstream and downstream supply chain.

Optimizing logistics and traceability

Pharma logistics involves multiple external stakeholders ranging from suppliers and third-party logistics (3PL) partners to health care professionals and end users, often across borders and continents. With an integrated and efficient supply chain, pharma companies can more quickly produce and distribute products, driving down costs and reducing the time it takes for patients to receive their prescriptions or treatment.

Another benefit of an integrated pharma supply chain is the ability to improve tracking and monitoring the production and distribution of both ingredients and finished products. This allows pharma companies to swiftly identify and address potential issues before they impact patients, thereby reducing the risk of medication errors and the need for recalls.

– Horizontal integration improves the pharmaceutical companies’ ability to accurately produce and transfer serialization data within the supply chain to 3PL partners, authorities, wholesalers, hospitals and pharmacies. The complexity of this task is steadily increasing. At NNIT, we expect the regulatory requirements to expand. Within the next ten years, pharma companies will likely be required to also account for the quality and origin of all active ingredients going into a product, says Greg Cathcart.

Disease management communities empower patients

An integrated pharma supply chain can also provide patients with greater transparency and access to information about their medications. Increasingly, manufacturers participate in disease management communities which facilitate much closer contact between pharma companies, healthcare professionals and patients. In many cases, these dedicated communities provide both patients and professionals with new insights into disease management and direct feedback on how patients react to treatment.

By sharing data and information across the supply chain, pharma companies can empower patients to make more informed decisions about their treatment. This can include providing information about the safety and effectiveness of different medications, as well as information about potential side effects and interactions.

Improve compliance and adherence with digital tools

Digital tools, ranging from sensors monitoring the blood sugar of diabetes patients to wearable devices and mobile apps, also encourage better compliance and adherence, which creates better treatment outcomes. For example, by reminding patients to take their medication or alerting caregivers if unusual activity is detected.

– Overall, an integrated upstream and downstream pharma supply chain can greatly improve the treatment of patients by providing faster access to medications, improving the accuracy and quality of treatments, and empowering patients with greater transparency and access to information. By working together and leveraging the latest technology and best practices, pharma companies can create a more efficient and effective supply chain that ultimately benefits patients and improves their health, says Greg Cathcart.

Need help navigating the complexities of integrated pharma production?

The complex reality of modern pharma production increases the need for an end-to-end partner who can see the big picture, including technical expertise, manufacturing processes and regulatory guidance.

At NNIT, we can assist you with both business consulting, system implementation and operation, allowing you to make the best choices for strategy, technology and change management.

At NNIT, we can assist you with both business consulting, system implementation and operation, allowing you to make the best choices for strategy, technology and change management.

Download our whitepaper "The Pharma Factory of the Future is Fully Integrated"